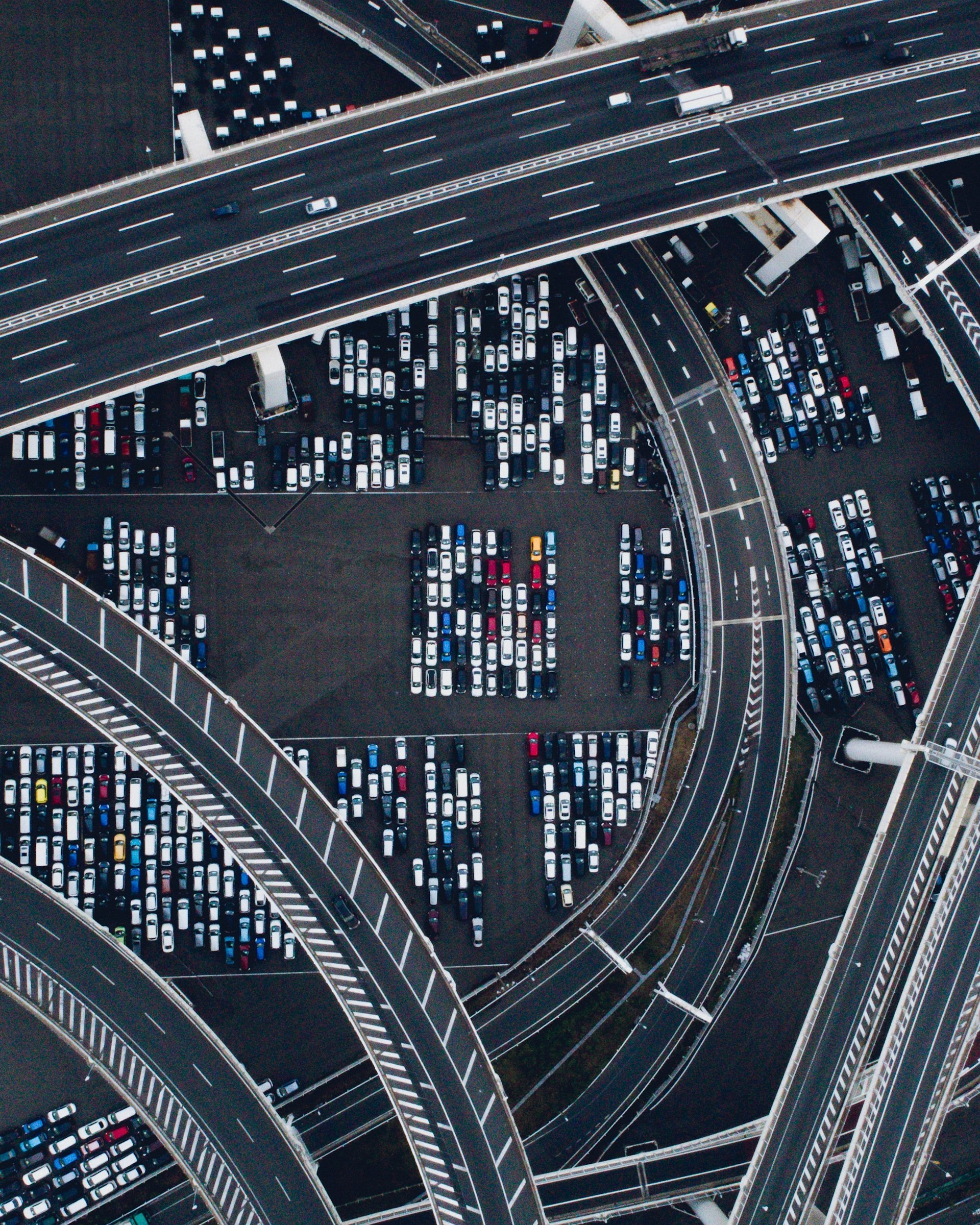

Building Sustainable Supply Chains: The Strategic Advantage in the Automotive Industry

Photo by Karen Vardazaryan on Unsplash

Introduction to Sustainable Supply Chains in Automotive

The automotive industry is at a pivotal moment. Global concerns about climate change, resource scarcity, and social responsibility are driving manufacturers and suppliers to rethink traditional supply chain models. Adopting sustainable supply chains is not just about environmental stewardship-it’s about building a resilient, competitive, and future-ready business that meets regulatory requirements and consumer expectations [1] .

This article explores the importance of sustainable supply chains in the automotive sector, offering practical strategies, real-world examples, and actionable guidance for implementation.

Why Sustainability Matters in Automotive Supply Chains

Environmental impact is a primary concern. The automotive supply chain-from raw material extraction to vehicle delivery-accounts for a significant portion of the industry’s total carbon footprint. By adopting sustainable practices, automakers can reduce emissions, conserve resources, and minimize waste [2] .

Business resilience is another key factor. Sustainable supply chains are more adaptable to disruptions caused by resource shortages, regulatory changes, and shifting consumer preferences. Companies that prioritize sustainability gain a competitive edge by ensuring long-term resource availability and operational efficiency [3] .

Regulatory compliance is increasingly critical as governments introduce stricter environmental, social, and governance (ESG) standards. Many countries require automakers to report on supply chain emissions and adhere to responsible sourcing practices [1] .

Consumer trust is built when brands demonstrate a genuine commitment to sustainability. Modern car buyers are more likely to support companies that show transparency in sourcing, manufacturing, and end-of-life vehicle management [5] .

Photo by Dmytro Bayer on Unsplash

Key Components of a Sustainable Automotive Supply Chain

Creating a sustainable supply chain in the automotive industry involves a holistic approach. Key elements include:

- Green procurement: Sourcing raw materials from responsible suppliers who follow ethical and environmentally friendly practices.

- Energy efficiency: Reducing energy consumption across manufacturing, logistics, and distribution by optimizing operations and investing in renewable energy sources.

- Waste reduction and recycling: Implementing circular economy principles by recycling vehicle parts and materials and designing vehicles for easier disassembly and material recovery [1] .

- Supply chain transparency: Using digital tools and technologies such as blockchain and IoT to monitor, track, and report on supply chain activities, ensuring compliance and traceability [2] .

- Social responsibility: Ensuring fair labor practices, human rights protection, and ethical sourcing throughout the supply chain [3] .

Real-World Examples and Case Studies

Many automotive leaders have begun integrating sustainability into their supply chain strategies:

- Electrification and Battery Recycling: Automakers are transitioning to electric vehicle (EV) production, which requires a new approach to sourcing critical minerals for batteries. Many are investing in battery recycling programs and forming partnerships to secure ethical, sustainable sources of lithium, cobalt, and nickel [1] .

- Digital Transformation: Companies are deploying IoT sensors and blockchain to track inventory, optimize logistics, and ensure transparency. These technologies help identify inefficiencies and reduce emissions across the entire supply chain [2] .

- Carbon Neutral Initiatives: Leading manufacturers have announced goals to achieve climate neutrality, not just in car manufacturing but across upstream suppliers and downstream logistics [5] .

Step-by-Step Guidance for Implementing Sustainable Practices

If your organization is looking to improve supply chain sustainability, consider the following steps:

- Assess Current Emissions and Resource Use: Start with a thorough audit of your supply chain’s environmental impact, including energy use, waste generation, and emissions. Involve stakeholders at every stage for a comprehensive review [4] .

- Set Clear Goals and Priorities: Based on your audit, identify areas where improvements are most needed. Set measurable, time-bound targets and define key performance indicators (KPIs) to monitor progress. Include smaller, achievable milestones to maintain momentum.

- Implement Emission Reduction Strategies: Options include adopting electric vehicles for short-haul logistics, optimizing routes to reduce fuel use, and recycling vehicle components at end-of-life. Choose strategies that align with your business model and scale implementation as capabilities grow [4] .

- Leverage Technology: Invest in digital platforms to enhance transparency, monitor supplier performance, and automate sustainability reporting. Technologies such as IoT, AI, and blockchain can provide actionable insights and ensure compliance [2] .

- Engage Suppliers and Partners: Collaborate with your suppliers to align sustainability standards and share best practices. Provide training, resources, and incentives to encourage broader adoption throughout your network [3] .

- Monitor, Report, and Improve: Establish regular reporting mechanisms to track progress and identify new opportunities for improvement. Use third-party audits and certifications where available to validate your achievements.

Potential Challenges and Solutions

Transitioning to a sustainable supply chain is not without obstacles. Common challenges include:

- High upfront costs: Investing in new technologies, processes, or materials can be expensive. To offset these costs, focus on long-term savings from energy efficiency, waste reduction, and improved operational performance.

- Complex global supply networks: Automotive supply chains are vast and interconnected. Start with key suppliers and gradually expand sustainability requirements across the network.

- Data and transparency gaps: Achieving full transparency can be difficult, especially with multiple tiers of suppliers. Use digital tools and demand regular data sharing to close these gaps.

If you encounter barriers, seek support from industry associations, join sustainability coalitions, or consult third-party experts for guidance.

Alternative Approaches and Innovations

While there is no one-size-fits-all approach, several innovative strategies are emerging:

- Shared mobility and car-sharing platforms: By maximizing vehicle utilization, these models can reduce overall production and resource demand [5] .

- Smart materials and lightweight design: Using recycled, bio-based, and lightweight materials not only improves fuel economy but also reduces the environmental footprint of manufacturing [5] .

- Regenerative braking and energy recovery systems: These technologies capture energy during vehicle operation, improving overall efficiency and reducing emissions [5] .

How to Access Resources and Opportunities

If you are seeking to implement sustainable supply chain practices:

- Contact your industry association for the latest sustainability guidelines and certification programs.

- Consult with recognized supply chain management consultants or sustainability experts for tailored strategies.

- Engage with technology providers specializing in digital supply chain management, IoT, and blockchain solutions.

- Stay informed about evolving regulations by visiting the official websites of relevant government agencies (such as the U.S. Environmental Protection Agency) or searching for “automotive supply chain sustainability standards.”

- Consider joining industry coalitions or forums focused on sustainable manufacturing and responsible sourcing.

When selecting partners or certification programs, verify their credentials and reputation through recognized industry sources and official channels.

Conclusion

Building a sustainable supply chain is a complex but rewarding journey for automotive organizations. By integrating environmental, social, and governance principles into every stage of the supply chain, companies can reduce risk, enhance brand reputation, and unlock new business opportunities. The time to act is now-embrace sustainability to ensure your place in the future of mobility.

References

- [1] Mayco International (2023). Exploring Sustainable Auto Industry Supply Chain Trends.

- [2] American Public University System (2023). Green Supply Chain Management in the Automobile Industry.

- [3] EMSNOW (2023). The Future of Automotive Supply Chains: Integrating Sustainability with Operational Efficiency.

- [4] Montway Auto Transport (2023). Guide to a Green Supply Chain in the Automotive Industry.

- [5] iPoint-systems (2023). Sustainability in the Automotive Industry.