Driving Innovation: How Digital Twins Transform the Automotive Industry

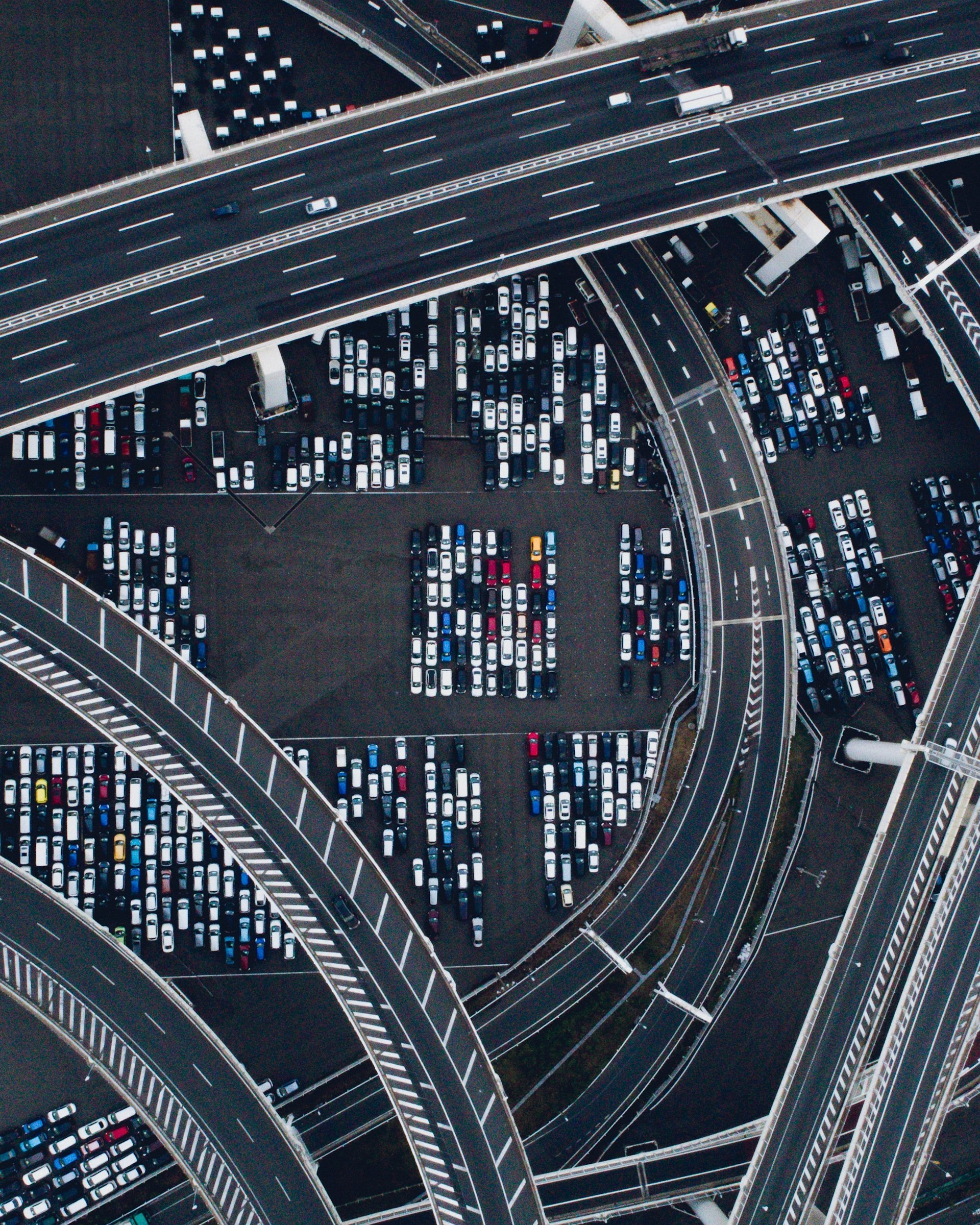

Photo by Xuan’s gallery on Unsplash

Introduction: The Digital Twin Revolution in Automotive

Digital twin technology is redefining how vehicles are designed, produced, and maintained. By creating precise virtual models of automotive components and entire vehicles, manufacturers can simulate, test, and optimize their products at every stage of the lifecycle. This innovative approach has rapidly become a cornerstone of modern automotive engineering, delivering substantial efficiency and quality improvements for leading carmakers like BMW and Volkswagen. [1]

Understanding Digital Twin Technology in Automotive

A digital twin is a real-time, data-driven virtual replica of a physical object or system. In automotive applications, digital twins are used to model vehicles, individual components, production lines, and even driving scenarios. These models continuously receive data from sensors, production systems, and field usage, enabling engineers to analyze performance, predict failures, and refine designs without the need for costly physical prototypes. [2]

The Impact on Automotive Design and Engineering

Traditionally, vehicle development relied on building multiple physical prototypes, leading to lengthy and expensive testing cycles. With digital twins, manufacturers can:

- Perform virtual prototyping , allowing engineers to test and refine designs in simulated environments, saving significant time and resources. [1]

- Optimize aerodynamics and energy efficiency by simulating vehicle performance under various conditions, such as extreme temperatures or high speeds.

- Test advanced materials like carbon fiber or composite structures for durability and safety, reducing the need for physical crash tests.

- Enhance electric vehicle (EV) battery design, as demonstrated by Volkswagen, which uses digital twins to analyze battery performance and longevity in diverse scenarios.

These capabilities enable manufacturers to launch vehicles faster, with fewer recall risks and greater confidence in real-world performance.

Smart Manufacturing and Production Optimization

Automotive giants, including BMW, have leveraged digital twins to create smart factories , where virtual models of production lines facilitate real-time monitoring and continuous improvement. The integration of platforms like NVIDIA Omniverse allows teams to collaborate remotely, test workflow changes, and identify inefficiencies without halting production. [1]

Implementing digital twins in manufacturing yields several benefits:

- Higher operational efficiency and reduced waste through process simulation and optimization.

- Real-time visibility into production environments, enabling rapid response to bottlenecks or quality issues. [3]

- Improved regulatory compliance, especially for critical components like EV batteries, by maintaining comprehensive digital records and product passports.

For implementation, manufacturers typically start by mapping existing workflows and integrating sensors across production assets. Data from these sources feed into the digital twin, which can be visualized using software tools for simulation and analysis. Collaborative platforms enable global teams to participate in process refinement.

Predictive Maintenance and Quality Assurance

One of the most transformative impacts of digital twins is in predictive maintenance . By continuously monitoring vehicle performance through real-time data streams, manufacturers can anticipate faults before they occur, minimizing costly recalls and improving customer satisfaction. [2]

For example, sensors embedded in vehicles relay data on engine health, battery status, and electronics back to digital twins. Machine learning algorithms analyze this data to predict component failures, enabling timely interventions and reducing downtime.

To access predictive maintenance solutions, automakers and fleet operators can:

- Work with vehicle OEMs to enable data sharing and integrate digital twin platforms into fleet management systems.

- Collaborate with technology providers specializing in automotive IoT and analytics to deploy sensor networks and cloud-based monitoring tools.

- Regularly review service schedules informed by digital twin predictions to optimize maintenance intervals.

Challenges include ensuring data security and interoperability among diverse vehicle platforms. Many organizations address these issues by following industry best practices for cybersecurity and standardizing data formats.

Supply Chain Optimization and Sustainability

Digital twins also play a vital role in supply chain orchestration . By simulating supply routes and logistics, manufacturers can forecast risks, minimize costs, and lower their carbon footprint. [3]

For implementation, automotive companies generally:

- Map supplier networks and logistics workflows in digital twin platforms.

- Use simulation tools to test alternative routes and inventory strategies.

- Analyze the environmental impact of different scenarios to support sustainability goals.

Organizations can find supply chain digital twin solutions by searching for specialized logistics technology providers or consulting with major automotive software vendors.

Enhancing Customer Experience and Sales

Beyond engineering and production, digital twins are reshaping the customer journey. Automakers use virtual models to create photorealistic renders and interactive 3D configurators, allowing buyers to customize vehicles online and visualize features before purchase. [3]

For post-sale engagement, digital twins enable continuous monitoring, updates, and retrofitting. Customers benefit from proactive service notifications and software upgrades, enhancing vehicle reliability and satisfaction.

To access these services:

- Check official manufacturer websites for online configurators and virtual showrooms.

- Contact dealership customer service for details on digital twin-enabled maintenance and monitoring programs.

- Inquire about connected car features and remote diagnostics when purchasing a new vehicle.

Case Studies: Leading Automotive Innovators

BMW’s adoption of digital twin-powered smart factories has resulted in streamlined production and improved product quality. The company’s partnership with NVIDIA has enabled real-time collaboration and rapid process innovation. [1]

Photo by Giuseppe Argenziano on Unsplash

Volkswagen, meanwhile, uses digital twins to optimize EV battery design, reducing development time and enhancing reliability. Molex engineers apply digital twins to electronic components for predictive validation, minimizing recall risk and improving lifecycle management. [5]

Automotive suppliers and OEMs are encouraged to explore partnerships with technology firms and invest in digital twin platform integration to remain competitive in this rapidly evolving landscape.

Challenges and Future Prospects

Implementing digital twin technology poses challenges such as data privacy, integration with legacy systems, and the need for skilled personnel. However, solutions include adopting cybersecurity best practices, leveraging cloud-based platforms for scalability, and investing in workforce training. [4]

Looking ahead, the market for automotive digital twins is projected to reach $73.5 billion by 2027, driven by growing adoption in design, manufacturing, and maintenance. [2] The technology will increasingly support autonomous driving simulation, regulatory compliance, and sustainability initiatives, offering new opportunities for innovation and operational excellence.

How to Get Started with Automotive Digital Twins

If you are an automotive manufacturer, supplier, or fleet operator considering digital twin adoption, follow these steps:

- Map your current engineering, production, and maintenance workflows.

- Identify areas where simulation and predictive analytics can deliver the greatest impact.

- Engage with digital twin platform providers and technology partners for pilot projects.

- Ensure robust data management and security protocols are in place.

- Train staff in digital twin tools and analytics.

You may consult with established automotive technology providers for tailored solutions or search for “automotive digital twin platforms” to review available offerings. For supply chain or regulatory compliance needs, seek out industry-specific software vendors or contact your national automotive trade association for guidance.

Conclusion: Leading the Future of Automotive with Digital Twins

Digital twins are driving unprecedented change in the automotive industry, from design and production to customer engagement and sustainability. By embracing this technology, organizations can reduce costs, enhance quality, and position themselves at the forefront of innovation. Multiple pathways are available to access these benefits, including partnering with technology providers, investing in workforce training, and leveraging cloud-based platforms. The journey to a smarter, more agile automotive future begins now.

References

- [1] ATT (2024). The Role of Digital Twin Technology in the Automotive Industry.

- [2] Toobler (2023). A Guide on Digital Twin in Automotive Industry.

- [3] Trask (2023). Digital Twins and the Industrial Metaverse: Transforming the Automotive Industry.

- [4] TXOne (2023). The Digital Twin Automotive Revolution: An Ultimate Guide.

- [5] Molex (2024). Predicting Automotive Electronics Performance with Digital Twins.