How Blockchain Is Transforming the Automotive Supply Chain

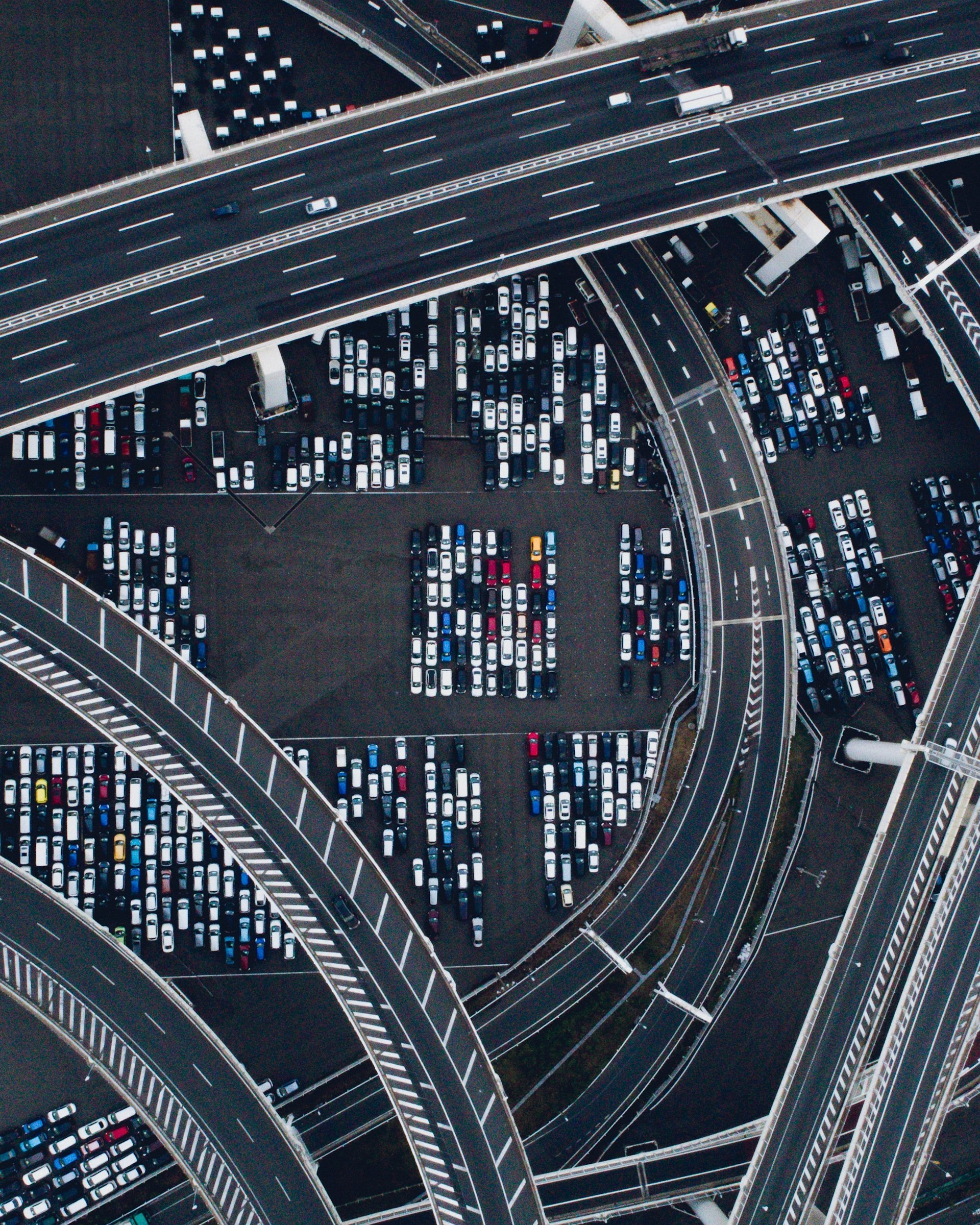

Photo by Jefferson Sees on Unsplash

Introduction

The automotive supply chain is an intricate web spanning manufacturers, suppliers, logistics providers, retailers, and customers worldwide. Managing this complexity has historically been a challenge, especially when it comes to verifying parts, tracing component origins, and ensuring the authenticity of products. Blockchain technology is emerging as a transformative force, offering powerful solutions to these challenges through transparent, tamper-proof recordkeeping and real-time data sharing across the entire supply chain [3] . This article explores the key roles blockchain plays in the automotive supply chain, provides actionable implementation steps, and highlights real-world examples and practical considerations for businesses seeking to leverage this technology.

Enhancing Parts Traceability and Authenticity

One of the most critical functions of blockchain in the automotive sector is establishing end-to-end traceability for every part and component. Each action-such as the creation of a part, its transfer between suppliers, or its installation in a vehicle-can be recorded as a unique transaction on a secure, distributed ledger [1] . This ensures:

- Real-time tracking from raw material sourcing to final assembly

- Verification of component authenticity to combat counterfeiting

- Efficient identification and recall of defective parts

For example, ARXUM offers blockchain-based solutions enabling automotive companies and customers to trace individual parts back to their manufacturers , ensuring accountability and transparency throughout the supply chain [2] . To implement this, manufacturers can:

- Assign each component a unique identifier (such as a digital certificate or QR code)

- Record every transaction and process step in a blockchain ledger accessible to authorized supply chain partners

- Develop user interfaces for easy searching and verification by inspectors, partners, and even end customers

Challenges may include the initial cost of digitizing legacy processes and training staff. However, the benefits in fraud prevention and operational efficiency can significantly outweigh the investment.

Streamlining Warranty Claims and Recall Management

Warranty claims and recalls are expensive and time-consuming for automotive manufacturers. Blockchain-based records of vehicle service histories and part authentications can eliminate fraudulent claims and reduce processing times [1] . By storing immutable records of installations, repairs, and part replacements, manufacturers and dealers can instantly verify warranty eligibility and parts provenance.

To implement this, automotive businesses can:

- Integrate service centers and dealers into a shared blockchain network

- Require digital recording of every part installation, replacement, and service event

- Develop automated smart contracts to validate and process warranty claims based on blockchain data

For example, Daimler has used blockchain to track cobalt sourcing and reduce CO2 emissions , further demonstrating blockchain’s value in sustainability and compliance documentation [2] .

Securing Shipping and Logistics

Automotive logistics involve multiple handoffs and documentation points, often leading to information silos and inefficiencies. Blockchain provides a secure, tamper-proof repository for cargo documents and shipping events [5] . Companies like Maersk have partnered with IBM to use blockchain for real-time tracking, document automation, and secure data sharing among all supply chain members.

Key steps for leveraging blockchain in logistics include:

- Digitizing shipping and customs documents for entry into a blockchain ledger

- Setting up permissions for all stakeholders-carriers, customs brokers, ports, and manufacturers

- Using smart contracts to automate verification and release of cargo at each checkpoint

This approach can eliminate redundant paperwork, reduce fraud, and provide all parties with instant access to shipment status, resulting in fewer delays and lower costs.

Improving Vehicle Lifecycle Management

Blockchain technology enables the creation of a digital certificate for every vehicle , recording its manufacturing details, ownership history, service records, and accident history [1] . This can enhance resale value, assist in regulatory compliance, and support end-of-life recycling processes.

To set up this system, manufacturers and industry consortia may:

- Define the data model for vehicle certificates, including all required lifecycle events

- Establish a consortium of OEMs, dealers, insurers, and regulators to govern access and updates

- Develop user-facing portals for prospective buyers and authorities to verify vehicle histories

BMW’s partnership with VeChain and Koopman’s collaboration with IBM are examples of how leading automotive companies are adopting blockchain to manage vehicle data and streamline handovers [4] .

Combating Counterfeit Parts

Counterfeit automotive parts are a persistent threat to safety and brand reputation. Blockchain’s immutable records provide a robust solution to authenticate genuine parts and expose fakes [3] . By recording every step in a part’s journey, from manufacturer through each distributor to final installation, blockchain makes it nearly impossible for unauthorized parts to enter the supply chain undetected.

To utilize this capability, supply chain managers can:

- Require suppliers to register all parts with blockchain-based IDs

- Integrate blockchain scanning at checkpoints and service centers

- Educate customers and partners about how to verify authenticity using publicly accessible blockchain records

This method not only protects consumers but also reduces liability and recall risk for manufacturers.

Increasing Transparency and Building Trust

The automotive supply chain involves numerous stakeholders who must trust each other’s data and processes. Blockchain’s transparency and distributed nature build trust by allowing all parties to verify records independently [3] . For example, Daimler has implemented blockchain initiatives to track emissions and ensure ethical sourcing, while IOTA and Volkswagen have partnered to secure data sharing between connected vehicles and infrastructure [4] .

Photo by Roshni Sidapara on Unsplash

To maximize the benefits of blockchain for transparency, companies can:

- Establish cross-company governance frameworks for blockchain data sharing

- Encourage open standards and interoperability with other digital systems

- Provide training for staff and partners on blockchain data access and use

While some organizations may hesitate due to data privacy or competitive concerns, blockchain platforms can be configured with granular permission controls to address these issues.

Step-by-Step Guidance for Adoption

For businesses considering blockchain in their automotive supply chain, the following steps can guide a successful transition:

- Assess Strategic Fit: Identify areas where traceability, security, and transparency are most critical-such as high-value parts, warranty management, or logistics.

- Select a Blockchain Platform: Evaluate enterprise-ready solutions such as IBM Blockchain, VeChain, or custom implementations, taking into account integration needs and scalability.

- Engage Stakeholders: Involve suppliers, logistics partners, and retailers early to ensure buy-in and cooperation across the supply chain.

- Develop a Pilot Project: Begin with a focused test case-such as tracking a single part category or automating a warranty process-and measure its impact.

- Scale and Integrate: Gradually expand blockchain implementation, integrating with ERP, IoT, and existing supply chain management systems.

If you are seeking support for blockchain adoption, you can consult with established technology providers such as IBM or seek guidance from major industry consortia. For practical next steps, consider searching for “automotive blockchain consulting” or visiting the official websites of leading blockchain solution providers to review their automotive case studies and offerings.

Potential Challenges and Solutions

While blockchain offers significant benefits, businesses may face challenges such as integrating with legacy systems, achieving industry-wide adoption, and balancing transparency with data privacy. Solutions include:

- Starting with modular blockchain pilots that can integrate with existing IT infrastructure

- Joining or forming industry alliances to promote standardization and interoperability

- Implementing permissioned (private) blockchains where sensitive data is protected but transparency is maintained among authorized parties

Ongoing staff training and change management are essential for a smooth transition to blockchain-enabled processes.

Key Takeaways and Next Steps

Blockchain is reshaping the automotive supply chain by delivering new levels of transparency, security, and efficiency. From tracing parts and combating counterfeits to automating claims and revolutionizing logistics, the technology provides versatile tools for industry-wide transformation. To get started, businesses should:

- Evaluate their current supply chain pain points

- Seek out blockchain solution providers with a proven record in the automotive sector

- Engage in industry working groups to stay informed on evolving standards and best practices

For further guidance, you can contact major automotive technology consultancies or industry associations and request information on blockchain pilot programs and funding opportunities. Ongoing research and collaboration are key to realizing the full potential of blockchain in this rapidly evolving industry.

References

- Kalp Studio (2023). Blockchain: The Future of Automotive Supply Chain Management.

- Scaling Parrots (2023). Blockchain and Automotive: 5 Examples of Applications.

- Webisoft (2024). Blockchain for Automotive: Exploring The Transformative Impact.

- Mike Entner-Gomez (2024). The Potential Impact of Blockchain Technology in Automotive.

- Cprime (2024). How is Blockchain Changing the Automotive Industry?