Unlocking Flexibility and Efficiency: The Strategic Value of Modular Car Architecture

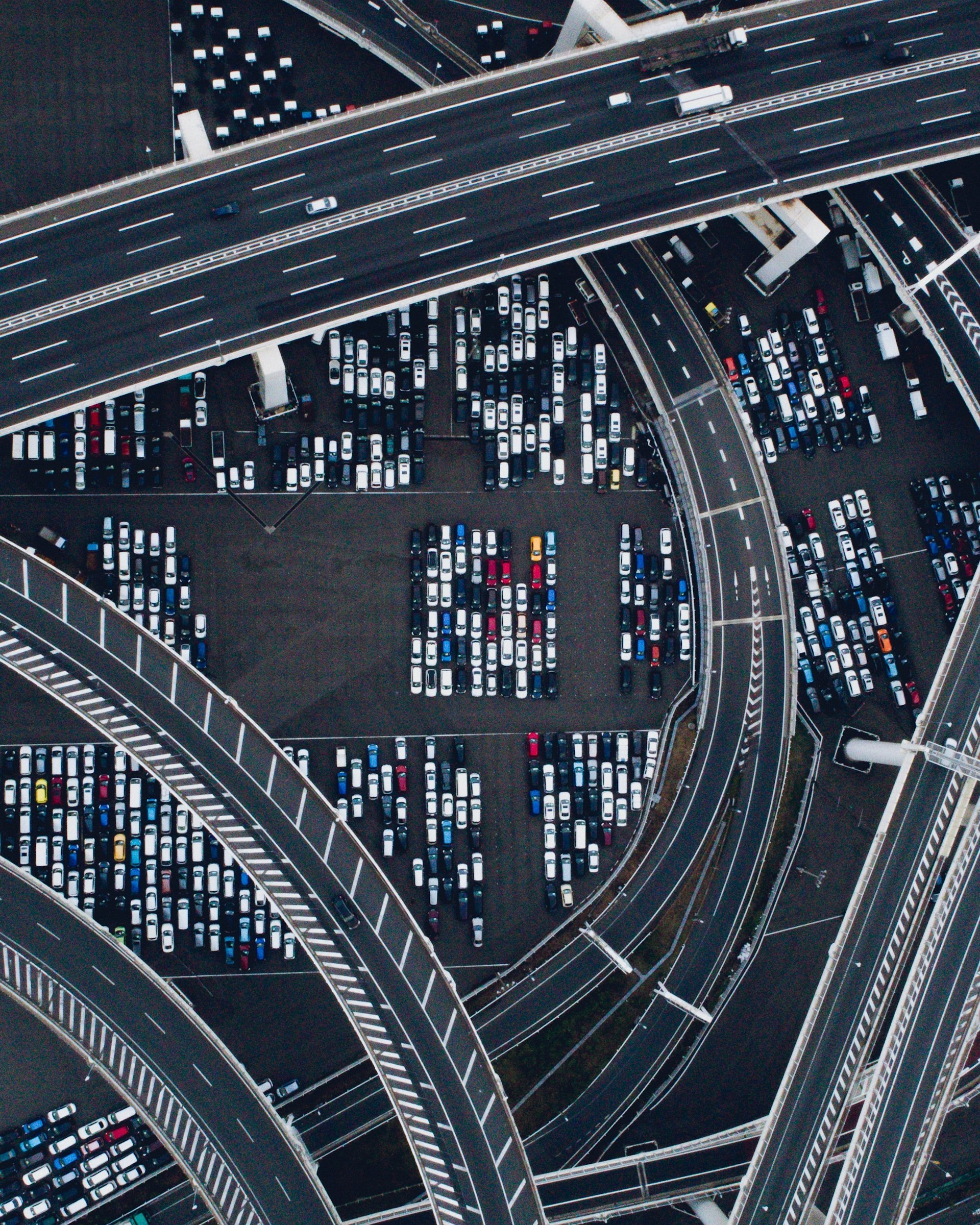

Photo by rawkkim on Unsplash

Introduction

In today’s rapidly evolving automotive landscape, modular car architecture has emerged as a transformative approach, redefining how vehicles are designed, manufactured, and customized. By leveraging standardized modules and shared platforms, this strategy delivers unparalleled flexibility, cost savings, and sustainability for both manufacturers and consumers. This article explores the critical importance of modular car architecture, its real-world impact, and actionable guidance for industry stakeholders and buyers alike.

What is Modular Car Architecture?

Modular car architecture refers to the design and manufacturing practice where vehicles are constructed from standardized, interchangeable modules. Each module-such as the powertrain, chassis, interior, or electronics-is developed to fit into a common platform, enabling multiple vehicle models to share core components. This approach contrasts with traditional vehicle production, where each model often requires bespoke parts and unique assembly processes. Leading automakers now employ modular platforms to expedite development, enhance customization, and streamline production lines [1] .

Key Benefits of Modular Car Architecture

1. Cost Savings and Economies of Scale

One of the most significant advantages is the reduction in production costs. By standardizing modules across various models, manufacturers minimize the need for unique parts, lowering design, tooling, and procurement expenses. For example, Volkswagen’s Modular Electric Drive Kit (MEB) platform enables the production of multiple EV models using shared components, resulting in substantial cost efficiencies [2] . These economies of scale benefit manufacturers and can translate into competitive pricing for consumers.

2. Increased Flexibility and Faster Time-to-Market

Modular architecture empowers automakers to swiftly adapt to changing market demands and technological advancements. When consumer preferences shift-such as increased interest in electric or hybrid vehicles-manufacturers can update or swap modules without overhauling entire production lines [1] . This flexibility accelerates time-to-market for new models, allowing rapid experimentation with innovative features and designs [2] .

3. Customization and Consumer Empowerment

Modular production supports greater vehicle personalization. Consumers can choose from a variety of modules-such as different engine types, interiors, or safety systems-to build vehicles tailored to their needs. This customer-centric approach encourages brand loyalty and increases satisfaction, as buyers gain more control over vehicle configuration without the high costs typically associated with bespoke manufacturing [1] . Automakers often provide online configurators or direct dealer support to guide customers through available options.

Photo by Ingrid Martinussen on Unsplash

4. Efficiency and Sustainability

Standardized modules streamline manufacturing, reducing complexity and enabling automated assembly line techniques. This efficiency speeds up production, isolates issues for quick resolution, and minimizes resource waste [3] . Furthermore, the ability to recycle or upgrade modules reduces environmental impact, supporting sustainability initiatives and regulatory compliance.

5. Reduced Waste and Improved Resource Management

Because components are shared across models, overproduction and scrap material generation are minimized. Manufacturers can better predict resource needs and avoid unnecessary surplus, making the entire supply chain more sustainable [1] . This approach aligns with growing industry emphasis on eco-friendly practices and circular economy principles.

Real-World Example: Volkswagen’s MEB Platform

The Volkswagen Group’s Modular Electric Drive Kit (MEB) exemplifies the benefits of modular architecture. MEB is used in models like the ID.3 and ID.4, sharing components such as battery packs, motors, and electronics. This platform utilizes advanced manufacturing techniques, including Flowdrill Friction Drill holes, which form robust threads in metal and eliminate the need for additional fasteners. The result is a lighter, more efficient assembly process and reduced production costs [2] .

Implementation: How Automakers Deploy Modular Architectures

Automakers typically begin by identifying core vehicle modules and designing them for compatibility across multiple models. Suppliers often assemble modules before shipping them to production facilities, where final assembly involves integrating these modules into a complete vehicle [4] . For manufacturers considering modular strategies, steps include:

- Assess existing product lines for modularization opportunities.

- Standardize interfaces and components to enable interchangeability.

- Engage suppliers in module pre-assembly to reduce storage and handling needs.

- Develop flexible assembly lines capable of integrating different modules as needed.

- Monitor market trends to update or introduce new modules efficiently.

For consumers, accessing modular customization typically involves visiting automaker websites or dealership showrooms, where staff provide guidance on available modules and configuration options. To explore models built on modular platforms, search for “modular architecture” or “platform sharing” on official manufacturer sites.

Challenges and Solutions

Despite its benefits, modular architecture presents challenges, such as initial development costs and the complexity of designing universally compatible modules. Automakers address these by investing in robust R&D, collaborating closely with suppliers, and leveraging digital tools for simulation and testing. For smaller manufacturers, partnerships or licensing agreements with larger firms can facilitate adoption of proven modular platforms.

Alternative Approaches and Future Trends

While modular architecture dominates current innovation, alternatives like zonal and domain architectures offer additional benefits. Zonal architectures, for instance, reduce cabling weight and simplify maintenance by structuring vehicle electronics into isolated hubs. Tesla’s adoption of zonal architecture in the Model 3 cut harness weight by 85%, improving range and performance for EVs [5] . As vehicles evolve to incorporate higher voltages and more complex electronics, modular and zonal approaches may converge, providing even greater efficiency and scalability.

Step-by-Step Guidance for Industry Stakeholders

If you are an automotive manufacturer or supplier looking to implement modular car architecture, consider the following steps:

- Conduct a comprehensive audit of existing vehicle designs to identify modularization potential.

- Develop standardized modules for core vehicle functions, ensuring compatibility across product lines.

- Collaborate with suppliers to create pre-assembled modules, reducing assembly time and storage requirements.

- Invest in flexible production lines that accommodate module integration and quick changeovers.

- Regularly review customer feedback and market trends to update or introduce new modules.

- Train staff and develop consumer-facing configurators to support personalized vehicle orders.

For consumers interested in customized vehicles, contact authorized dealerships or visit official automaker websites to explore available configuration options. Use search terms like “modular vehicle platform” and “customizable car design” for best results.

Conclusion: The Strategic Imperative of Modular Car Architecture

Modular car architecture is reshaping the automotive industry, delivering value through cost savings, flexibility, customization, and sustainability. Both manufacturers and consumers benefit from streamlined production, rapid innovation, and personalized vehicles. As the industry moves forward, modular design will remain central to meeting evolving market demands and regulatory requirements.

References

- Shoplogix (2024). Modular Vehicle Production: A Smarter Approach to Manufacturing.

- Flowdrill (2024). What Are The Advantages And Disadvantages Of EVs Being Built On The Same Modular Car Platform?

- Tencom (2024). The Benefits of Modular Design in Manufacturing.

- Mayco International (2024). Understanding Modular Design and Production in the Auto Industry.

- Molex (2024). Zonal Architecture vs. Domain Architecture: Modular Automotive Infrastructure Face-Off.